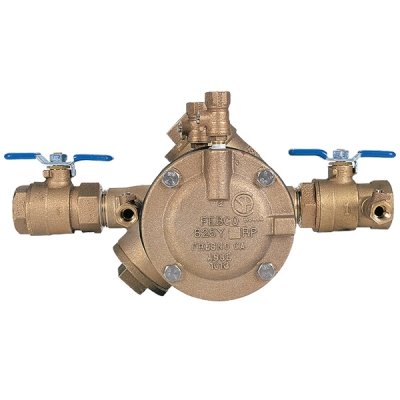

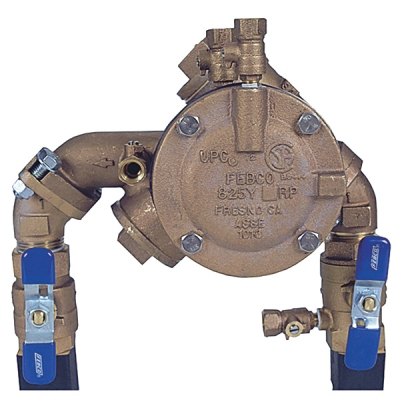

Febco 825Y-150 1 1/2" Reduced Pressure Assembly

Febco 825Y-150 1 1/2" Reduced Pressure Assembly.

Reduced Pressure assemblies are used to protect against high hazard (toxic) fluids in water services to industrial plants, hospitals, morgues, mortuaries, and chemical plants. They are also used in irrigation systems, boiler feed, water lines and other installations requiring maximum protection. They feature a bronze body and threaded ball valve shutoffs. Maximum Working Pressure: 175psi (12.1 bar).

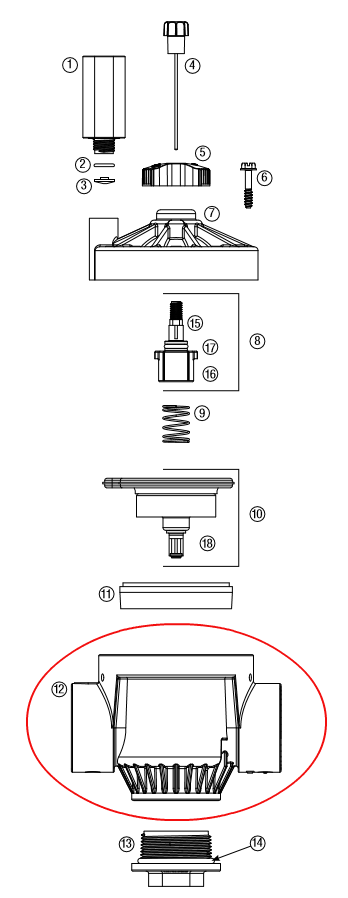

The reduced pressure zone assembly shall consist of two independently operating, spring loaded, "Y" pattern check valves and one hydraulically dependent differential relief valve. The assembly shall automatically reduce the pressure in the "zone" between the check valves to at least 5psi lower than inlet pressure. Should the differential between the upstream and the zone of the unit drop to 2psi, the differential relief valve shall open and maintain the proper differential.

Mainline valve body and caps including relief valve body and cover shall be bronze. Check valve moving member shall be center stem guided. All hydraulic sensing passages shall be internally located within the mainline and relief valve bodies and relief valve cover. Diaphragm to seat area ratio shall be 10:1 minimum. Relief valve shall have a removable seat ring. Check valve and relief valve components shall be constructed so they may be serviced without removing the valve body from the line. All seat discs shall be reversible. Shutoff valves and test cocks shall be full ported ball valves.

Specifications

- Size: 1 1/2"

- Maximum Working Pressure: 175 PSI (1200 KPa)

- Hydrostatic Test Pressure: 350 PSI (2400 KPa)

- Temperature Range: 32°F to 140°F (0°C to 60°C)

- End Connection: NPT ANSI / ASME B1.20.1

- Main Valve Body: Bronze

- Relief Valve Body: Bronze

- Elastomers: Nitrile Seat Discs

- Diaphragms: Nitrile, Fabric Reinforced

- Springs: Stainless Steel

Installation:

- Consult local codes for specific installation requirements and restrictions applicable to your area. It is recommended that system supply pressure be at least 20 psi

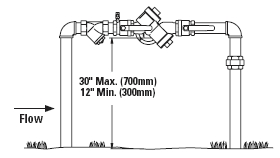

- These instructions apply to the FEBCO Series 825Y, sizes 3/4" - 2" only. The assembly should be installed in the horizontal position with the relief valve on the side.

- The valve assembly must be installed where it is accessible for periodic testing and maintenance. Clearances shown in the installation views apply to exterior, interior and pit/vault installations and are only recommendations. These minimums do not apply to removable protective enclosures. Refer to local codes for actual requirements in your area.

- PRIOR TO INSTALLING THE VALVE INTO THE LINE, FLUSH THE SUPPLY LINE OF ALL FOREIGN MATERIAL. Failure to flush the supply line may cause the check valves to become fouled and require disassembly and cleaning.

- After installation SLOWLY fill the assembly with water and bleed air from the body using the # 3 and # 4 test cocks. Test the valve assembly to ensure correct operation. NOTE: All assemblies are tested at the factory for proper operation and leakage. If the valve does not pass the field test, it is most likely due to a fouled check valve. This is not covered by the factory warranty, and the valve cover must be removed and the check seats inspected and cleaned. Any damage or improper operation caused by pipeline debris or improper installation/start-up is not included in the factory warranty. In case of a possible warranty claim, contact your local supplier or FEBCO Representative. DO NOT REMOVE THE VALVE ASSEMBLY FROM THE PIPELINE.

- The assembly must be protected from freezing and excessive pressure increases. Pressure increases can be caused by thermal expansion or water hammer. These excessive pressure situations must be eliminated to protect the valve and system from possible damage.

- Plastic testcock plugs and tethers are provided (loose in box) for areas that require them. Since bronze plumbing products contain detectable amounts of lead,

the State of California requires all manufacturers to issue the

following notice:

*WARNING: This product contains chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

|

|